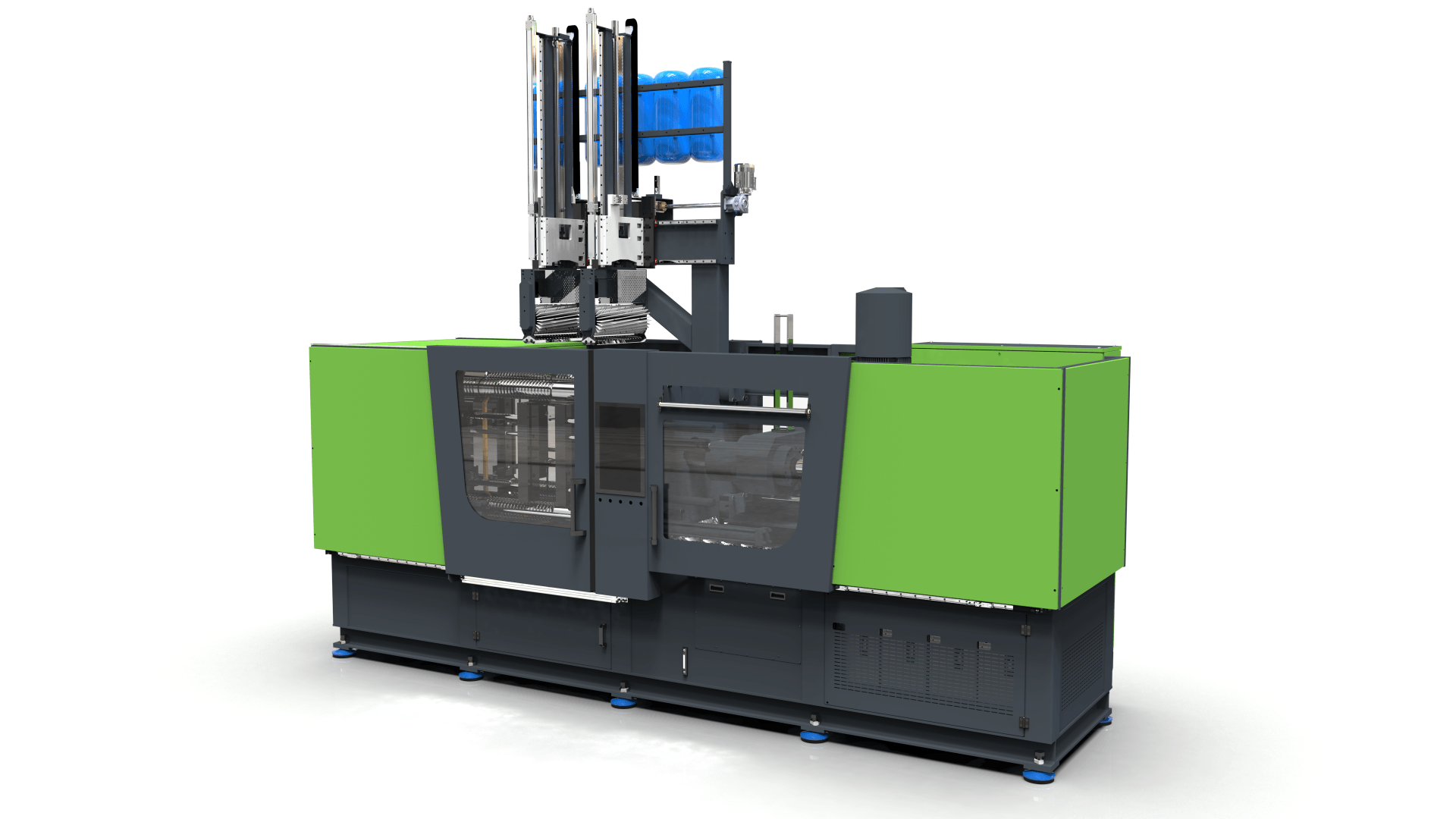

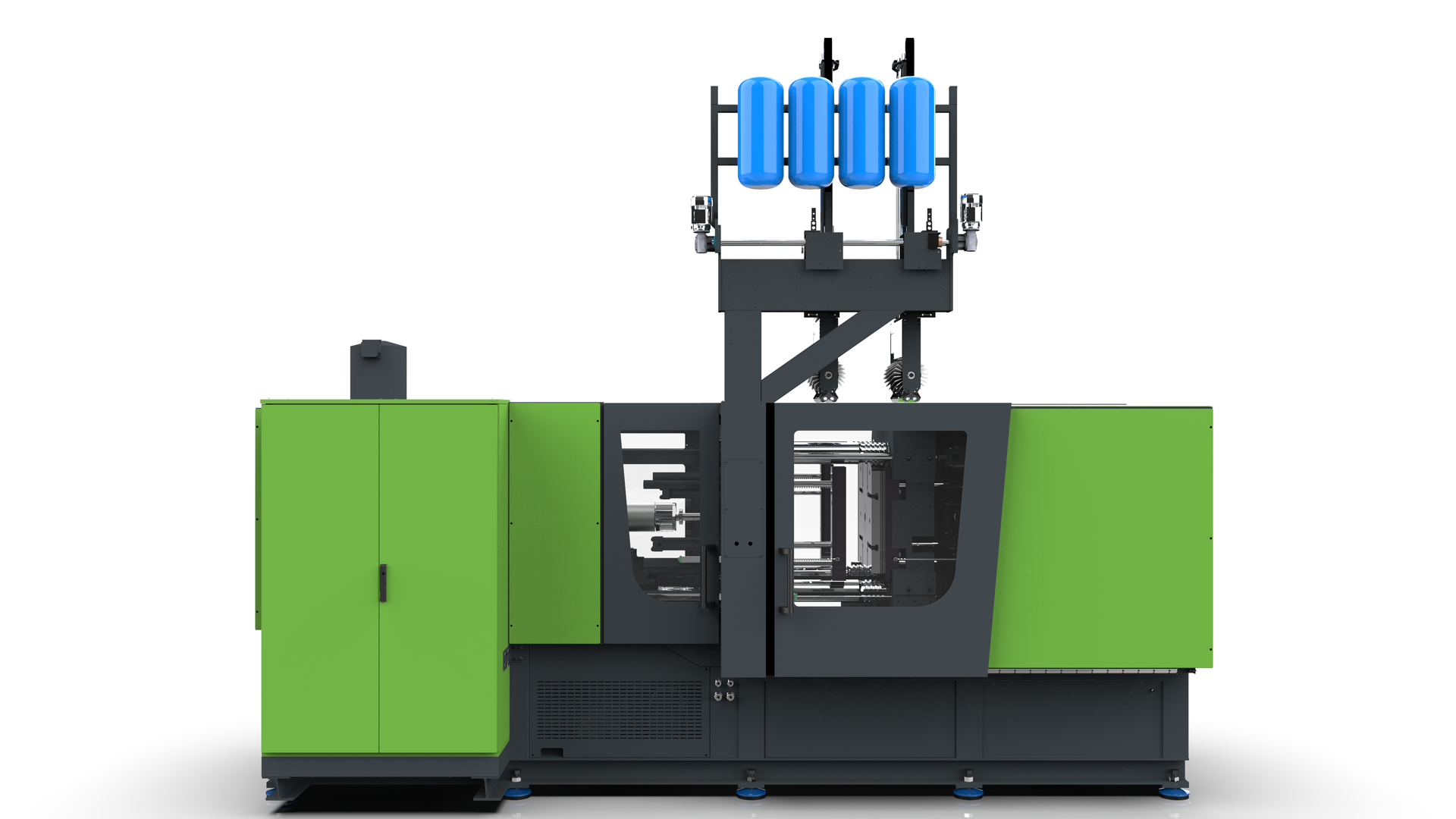

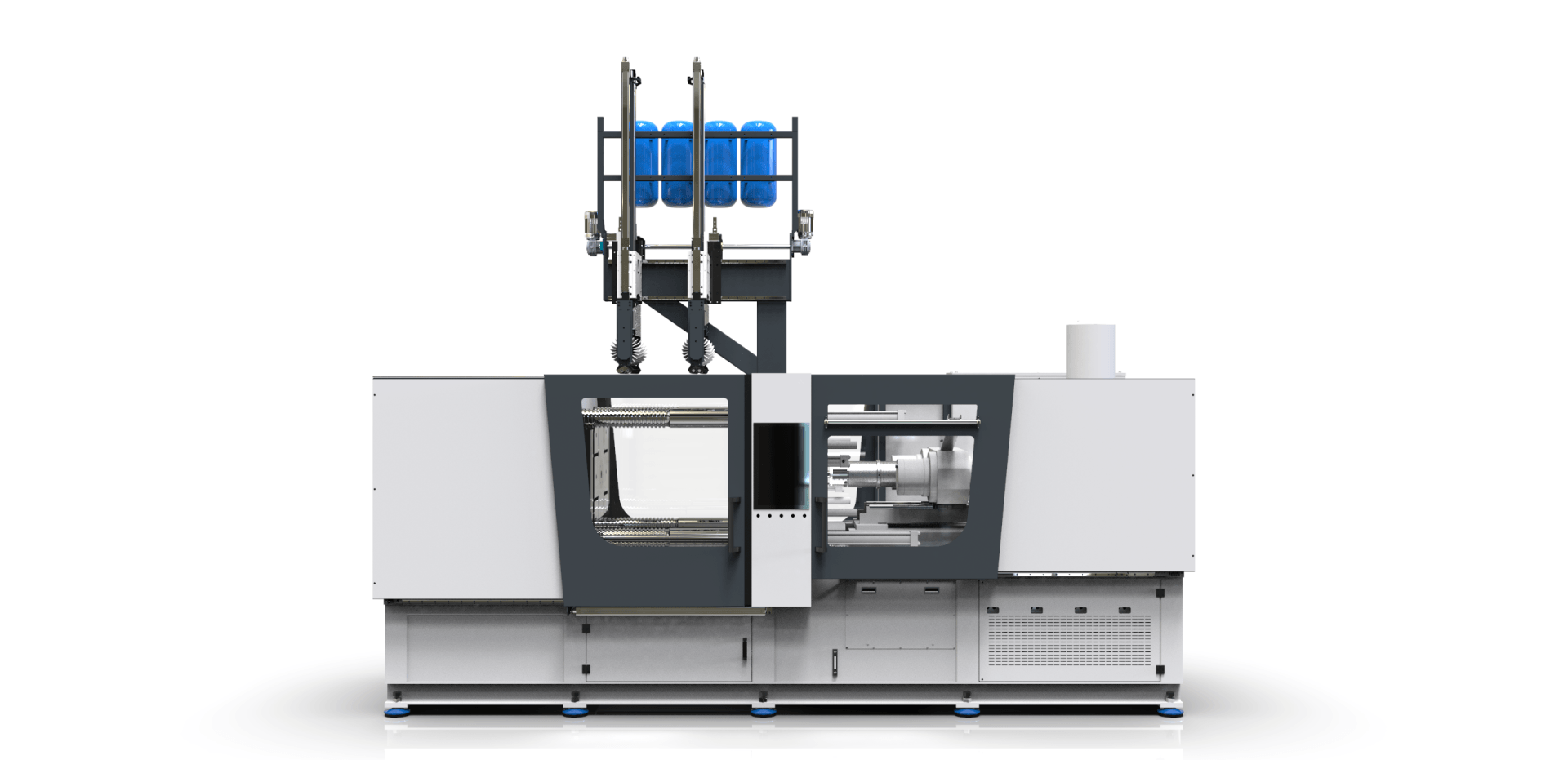

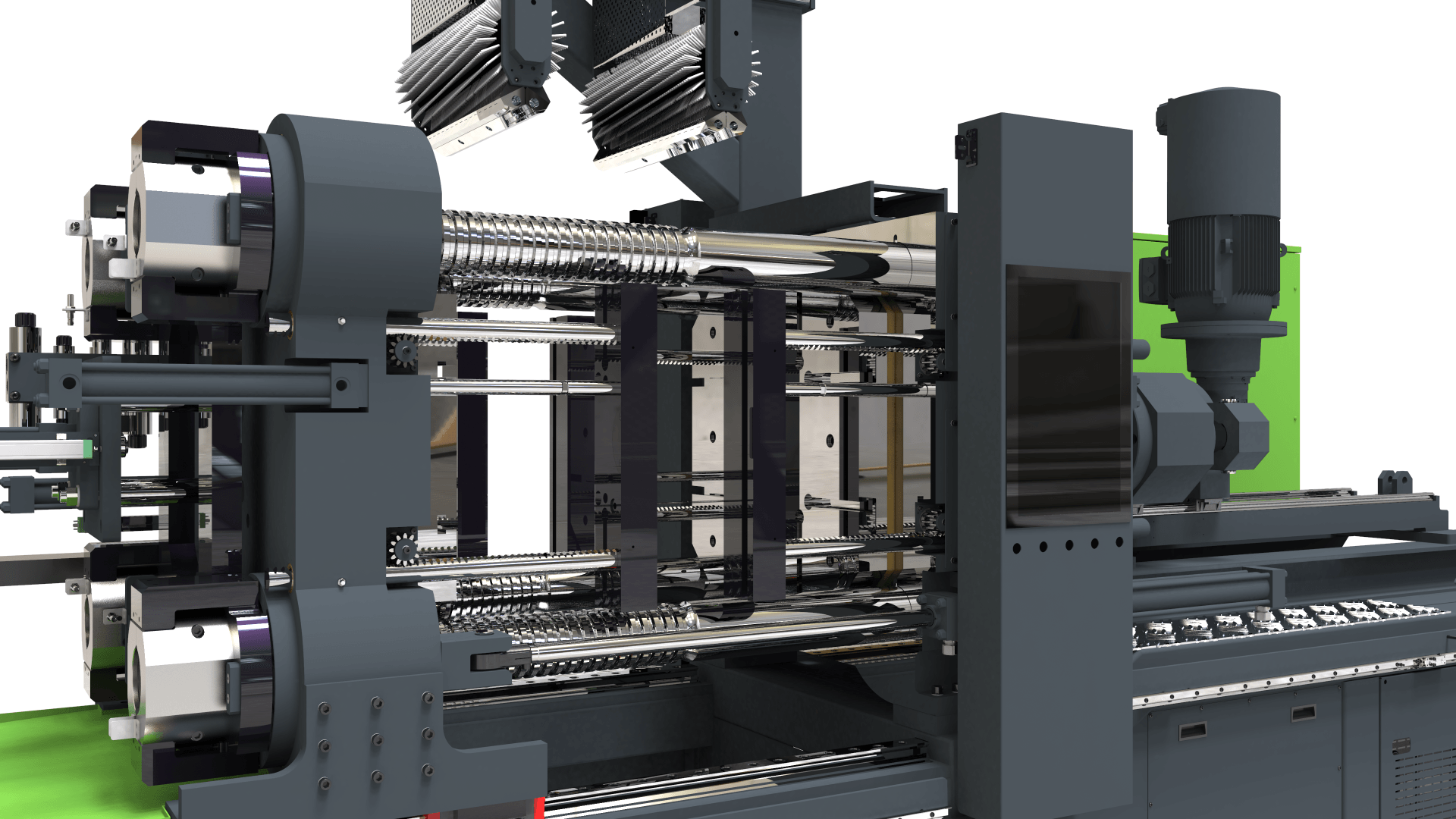

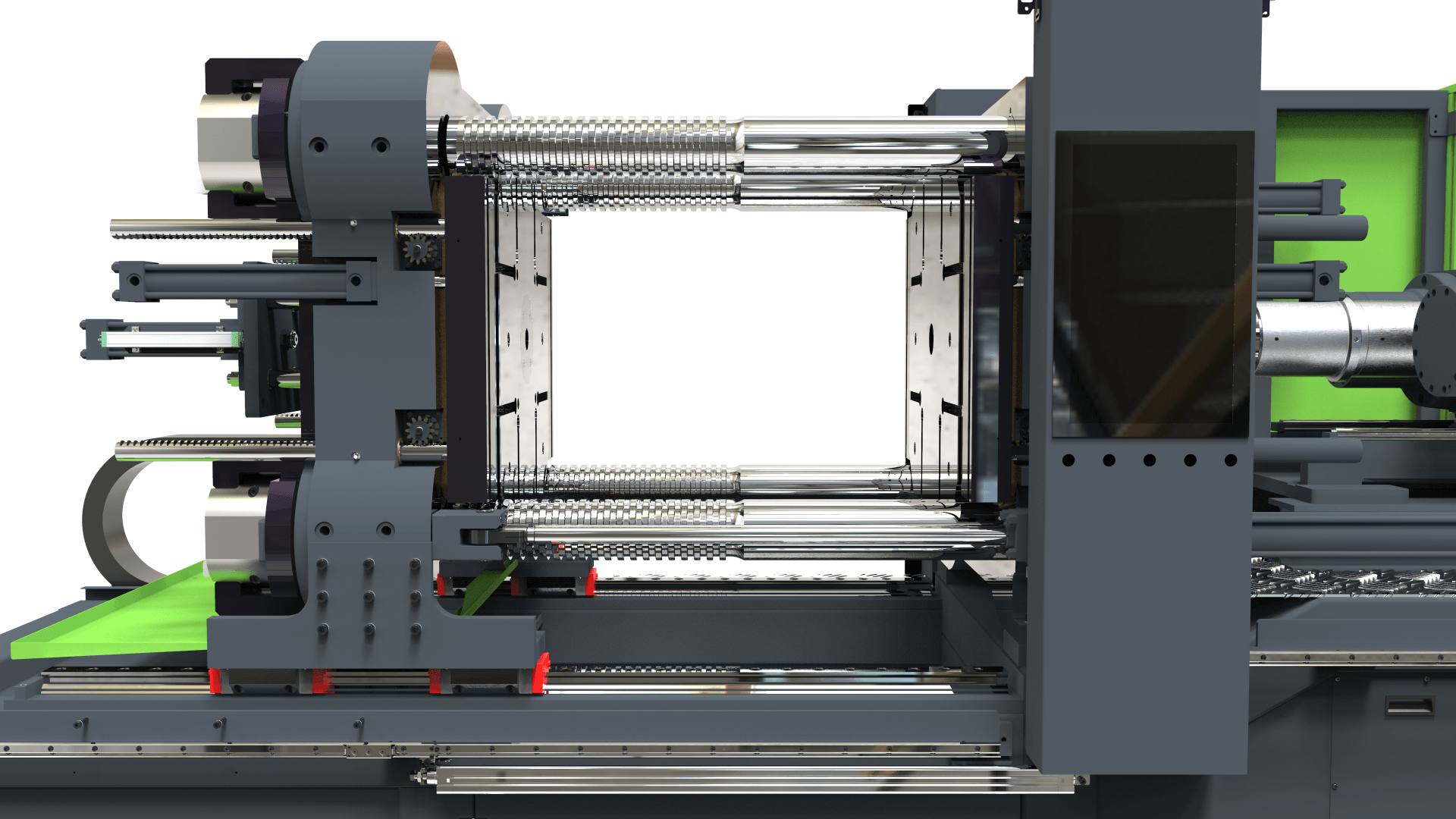

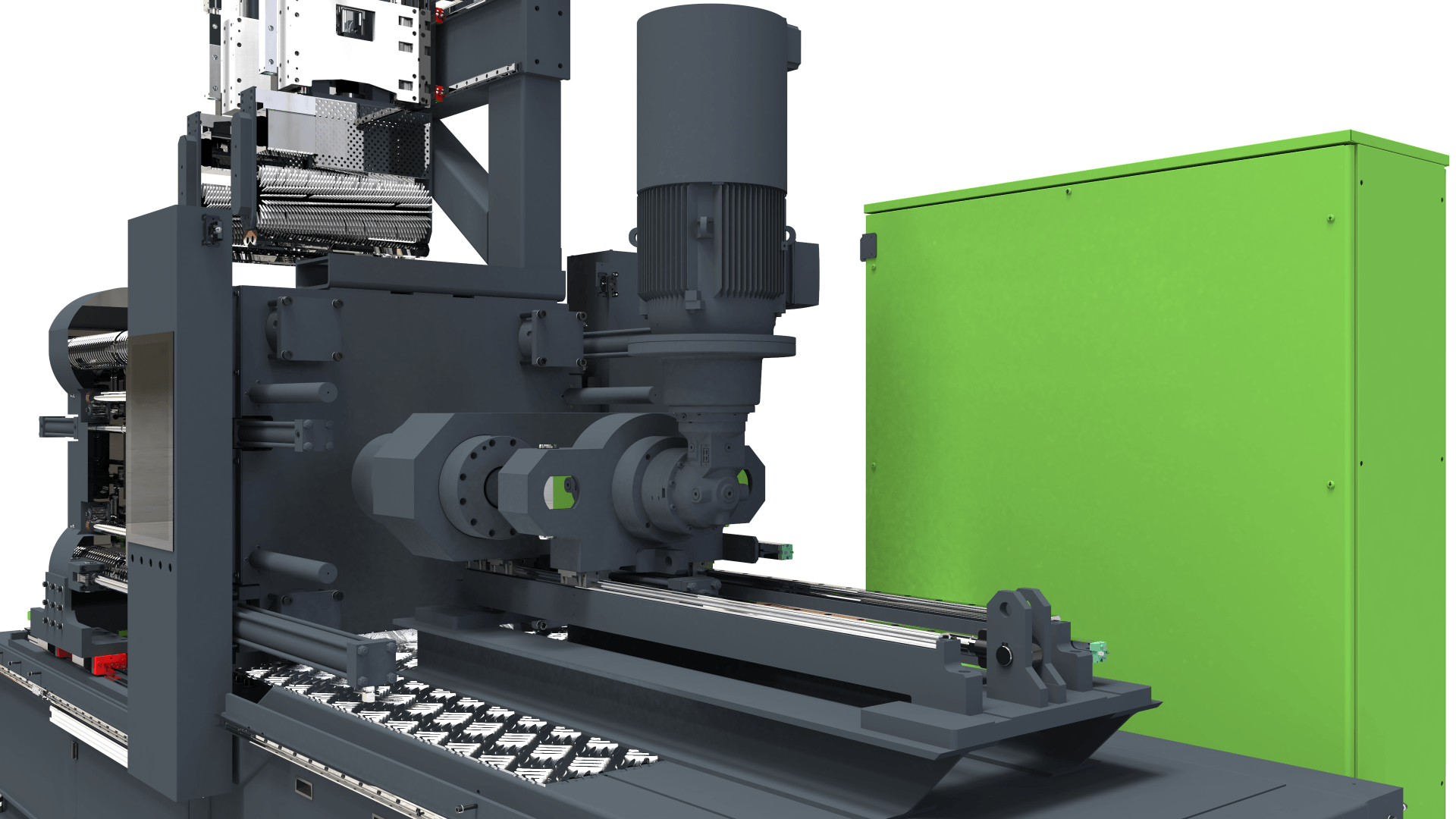

This series contains a servomotor with gear pump monitored by a latest generation drive.

The benefits of this system are multiple and guarantee a high level of performance such as:

- Accurate process control to ensure greater reduction in production waste

- Reduction in energy consumption due to the lower cooling requirement of the hydraulic system

- Less noise for a more comfortable working environment

- Longer life of the oil and hydraulic components with consequent reduction in maintenance costs

All these benefits have the declared objective of ensuring a more accurate molding process.

The servo-hydraulic system, combined with the software for optimizing energy savings, guarantees the end user a more profitable manufacturing process.